Using Carbon Capture and Storage Digital Twins for Net Zero Strategies

CO2 capture and storage technologies (CCS) catch CO2 from its production source, compress it, transport it through pipelines or by ships, and store it…

CO2 capture and storage technologies (CCS) catch CO2 from its production source, compress it, transport it through pipelines or by ships, and store it…

CO2 capture and storage technologies (CCS) catch CO2 from its production source, compress it, transport it through pipelines or by ships, and store it underground. CCS enables industries to massively reduce their CO2 emissions and is a powerful tool to help industrial manufacturers achieve net-zero goals. In many heavy industrial processes, greenhouse gas (GHG) emissions cannot be avoided in the required time frame and must use CCS solutions, as in the cement, fertilizers, and chemical industries.

Scenarios for reducing GHG emissions on a global scale highlight the role of CCS in the energy mix. To reach the 2° C objective, according to the IEA’s sustainable development scenario, more than 1,000 megatonnes (Mt) of CO2 each year would have to be stored by 2030 and a large number of CCS installations must be deployed from now until 2050.

Today, around 30 large-scale installations are operational, injecting around 40Mt of CO2 per year. The development of this technology will grow rapidly in the coming decade but this promising solution has yet to prove that it can be industrialized at an acceptable cost.

One of the key challenges for keeping CCS solutions economical is the cost of proving duration and reliability of storage using numerical modeling.

Traditional simulators for carbon sequestration are time-consuming and computationally expensive. Machine learning models provide similar accuracy levels while dramatically shrinking the time and costs required.

In the Accelerating Climate Change Mitigation with Machine Learning: The Case of Carbon Storage post, we explored the use of machine learning for modeling CCS on 2D homogeneous reservoirs. The model was limited to a single well for CO2 injection, and the reservoir was not permitted to have a slope.

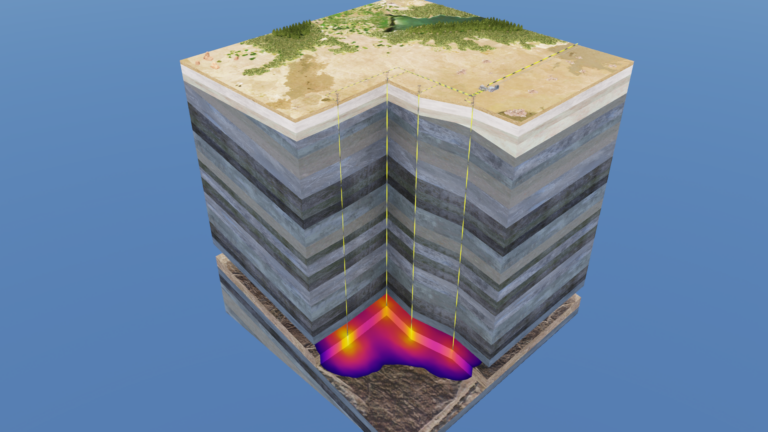

This post presents a new approach to carbon capture and storage that is substantially close to what is needed in industrial settings. It is readily available for real-world applications using NVIDIA Modulus and NVIDIA Omniverse. This CCS approach works on high-resolution, two-meter digital twin simulations over large spatial domains, handles a varying number of injection wells, and considers dipping and heterogeneous reservoirs. Most importantly, this new CCS method handles multiple wells and their interactions.

Data sources for physics-ML digital twins

This post specifically explores CO2 injection into 3D basin-scale dipping saline reservoirs through multiple wells over 30 years.

To generate the numerical simulations dataset for this multi-well problem, we used the local grid refinement (LGR) approach for reducing computational costs while ensuring high fidelity.

Figure 1 shows four levels of grid refinement around each injection applied to simulate the near-well CO2 plume migration and pressure buildup with high resolution. At level 0 (global), coarser grid cells are used to capture far-field pressure buildup and interactions between different injection wells. Going from levels 0 to 4, cell size is reduced by 80x on the x,y dimensions and 10x on the z dimension.

This work considers a wide range of practical input parameters, including:

- Reservoir conditions: Depth, temperature, and dip angle

- Injection schemes: Number of injection wells, rates, and perforation intervals

- Permeability heterogeneity: Mean, standard deviation, and correlation lengths

Each of these parameters was selected to cover the most practical cases for realistic CO2 storage sites.

As the reservoir has a variable dip angle, CO2 plumes tend to migrate up-dip due to buoyancy. The reservoir conditions such as initial hydrostatic pressure and temperature determine CO2 and water fluid properties. Also, due to the presence of the dip angle, the hydrostatic pressure can vary significantly around each injection well, creating various fluid properties even in the same basin.

As this work shows, thanks to these digital twins governed by physics-informed machine learning (physics-ML), industrial manufacturers can cheaply determine the following:

- Storage capacity, maximum safe pressure buildup, and maximum injection capacity

- Calculation of CO2 gas saturation plume and footprint

- Calculation of CO2 migration in dipping reservoirs

- Optimal well locations and injection rates

- Wide ranges of geostatistical variability, which requires a huge ensemble of evaluations at different points in parameter space

- Ways to alleviate the cost and time of evaluations when traditional numerical methods are prohibitive

- Efficient ways to explore engineering parameter space with an openly accessible web application that provides real-time predictions

- Industrial-scale projects using the Modulus and Omniverse platforms

4D simulation

A recent paper, Accelerating Carbon Capture and Storage Modeling Using Fourier Neural Operators, proposes a nested Fourier neural operator (FNO) architecture to predict in the domain with local grid refinements.

The computational domain of the Nested FNO is a 3D space with time:

In this equation,  is the time interval of 30 years and

is the time interval of 30 years and  is the reservoir domain. A sequence of FNO models is used to predict the 3D reservoir domain consisting of subdomains. At each refinement level, the original FNO architecture is extended into 4D to produce outputs for pressure buildup and gas saturation in the 3D space-time domain.

is the reservoir domain. A sequence of FNO models is used to predict the 3D reservoir domain consisting of subdomains. At each refinement level, the original FNO architecture is extended into 4D to produce outputs for pressure buildup and gas saturation in the 3D space-time domain.

The input for each model includes the following variables:

- Permeability field

- Initial hydrostatic pressure

- Reservoir temperature

- Injection scheme

- Spatial/temporal encoding

In CO2 storage, pressure buildup travels significantly faster than gas saturation. Because of this, an FNO model is first used to predict the pressure buildup at level 0 and to capture the global propagation and the interaction between wells. Then level 0 is fed pressure buildup predictions around each injection well to the FNO models on level 1.

Each subsequent model takes the input on the domain together with the coarser-level prediction and outputs the predictions on the finer level. By giving the coarser-level prediction to the finer-level model as an input, the boundary is provided the conditions of the finer-level subdomain.

Carbon capture and storage results over 30 years

As shown in Figures 2 and 3, Nested FNO successfully captures all the complex processes of plume migration. Overall, Nested FNO displays great generalization with small overfitting: the average saturation error for the gaseous CO2 plume is 1.2% for the training set and 1.8% for the testing set. This accuracy is sufficient for most practical applications, such as estimating sweep efficiencies as well as forecasting plume footprints for land acquisition or monitoring program design.

The relative pressure buildup error for the training and the testing set is 0.3% and 0.5%, respectively. Like the gas saturation, you can observe small overfitting for the training and testing set. This generalization is remarkable, considering the small training data size for this high-dimensional problem. Generalizability is achieved through a novel fine-tuning technique. For more information, see the original paper, Accelerating Carbon Capture and Storage Modeling.

In addition, Nested FNO offers real-time forecasts, where the inference speed is 700,000x faster compared to the state-of-the-art numerical solver. The fast inference enables many critical tasks for CCS decision-making that were prohibitively expensive.

For example, in the paper, a rigorous probabilistic assessment for maximum pressure buildup and CO2 plume footprint is presented. This type of assessment can reduce uncertainties in capacity estimation and injection designs. However, it would have taken nearly 2 years with numerical simulators. Using Nested FNO, this assessment took only 2.8 seconds.

Real-time digital twins

The trained Nested FNO can provide real-time predictions. It is hosted on a public GPU-based web application. You can construct any random combination of reservoir condition, injection scheme, and permeability field characteristics and obtain instantaneous predictions of gas saturation, pressure buildup, and sweep efficiency estimates.

The web app promotes equity in CO2 storage project development and knowledge adoption. This especially benefits small- to mid-sized developers as well as communities that want an independent evaluation of projects being proposed. High-quality forecasts were previously unattainable for these important players.

Industry-ready CCS platforms

Video 1 shows the process of storing CO2 in an underground reservoir consisting of saline aquifer on simulation data taken from Accelerating Carbon Capture and Storage Modeling Using Fourier Neural Operators. The CO2 arrives at the surface facility, from which it is distributed to four wells and pumped to the underground reservoir. Inside the reservoir, pressure buildup and evolution of CO2 saturation are shown over a 30-year period. The video was produced in Omniverse and the simulation data was prepared in ParaView for visualization.

The building blocks outlined in this post form a basis for a carbon capture and storage digital twin with the closest realistic setting possible to serve the industry’s needs. NVIDIA technology was used as a basis to achieve a transformative AI-powered CCS digital twin with interactivity at scale. With the NVIDIA digital twin platform, you can predict, visualize what will happen, and interact with the model to ensure the safety and reliability of your storage.

More precisely, using the NVIDIA digital-twin framework for scientific computing brings an era of million-x scale advances enabled by AI and accelerated computing. This framework encompasses two major platforms: Modulus and Omniverse.

Physics-ML framework built with Modulus

NVIDIA Modulus is a physics-ML framework for developing physics-based, machine-learning models. It blends the power of physics in the form of governing differential equations with data to build high-fidelity, parameterized surrogate models for designing digital twin models for complex non-linear, multi-physics systems.

Modulus takes both data and governing physics into account to train a neural network that creates an AI surrogate model for digital twins. The surrogate can then infer new system behavior in real time, enabling iterative workflows. Modulus enables data-driven training using FNO, and the latest release of Modulus incorporates Nested FNOs.

Nested FNOs can be trained on CCS reservoir simulation data to develop parametrized surrogate models. This means that a single model can potentially analyze different reservoir conditions with a variable number of wells, their positions, and injection schemes.

Modulus includes a range of features like various novel architectures, training pipelines, data loaders, and optimizers for both training and inference. This physics-ML platform also includes multi-GPU and multi-node scaling. With all these features, Modulus can enable you to build performant deep-learning software to model CCS reservoirs with little cost and time.

Virtual reality with Omniverse

NVIDIA Omniverse is an open-source-source platform for building virtual worlds. It provides an interactive environment where stakeholders can ask what-if questions about the future and can visualize the consequences of their actions.

The Omniverse interoperability and customizable user experience, combined with the capability to produce a high-quality visual representation of results, makes it an ideal tool for building digital twins. In short, Omniverse plays the role of a data directory as it tracks the state of datasets. It is also the driver, orchestrator for processing pipelines (compute resource management and progress monitoring), and the visualization engine.

NVIDIA provides an entire spectrum of technologies to build digital twins based on Omniverse:

- Omniverse Nucleus for model and data exchange

- The Omniverse user interface for real-time feedback and interactivity

- AI and Modulus for building powerful, physics-guided AI systems

- Incredible CPU, GPU, and DPU chips for AI training and inference

Using Omniverse provides a user interface that transforms data into meaningful information. Data can come from a disk or from ParaView, but it can also come from any software that’s directly connected to Omniverse.

You can write extensions that enable interaction between Omniverse and any software. Next, build a custom user interface for the problem at hand and enable an intuitive exploration of the parameter space. Real-time interaction is possible if the connected software delivers results fast enough. There’s a connector to Modulus, in such a way that, after training the physics-ML model, you need only perform inference and then enjoy the real-time experience.

Omniverse was used to enable impactful, real-time visualization of the output of the 4D carbon storage simulation showcased in Video 1. Specifically, this video navigates through a storage site and shows results of pressure buildup and gas saturation.

Using Omniverse enables you to couple multiple systems in one stage. For example, you can have a reservoir twin coupled to a digital twin of a surface facility that compresses and injects CO2 and then observes their interactions.

AI-powered, real-time, 4D digital twins have arrived

Simulation of the storage part of CCS, involving injecting carbon dioxide into underground reservoirs, requires a solution to a detailed, high-resolution problem. Numerical methods are extremely slow for solving the governing equations of this problem.

The Nested FNO, for four-dimensional spatial-temporal modeling, speeds up predictions by nearly 700,000x. The speed and accuracy of this model enable uncertainty quantification and risk assessment in a few minutes rather than decades.

You can find the Nested FNO model in the /NVIDIA/modulus-launch GitHub repo to train on your own dataset and create the digital twin of your reservoir. A first CCS visualization was also completed using Omniverse based on the recent results in Accelerating Carbon Capture and Storage Modeling Using Fourier Neural Operators. This work is the base for building a large-scale CCS digital twin for climate mitigation jointly with several industrial partners.

The NVIDIA platform for scientific digital twins accelerates physics-based machine learning models to solve million-x scale science and engineering problems thousands of times faster than previously possible:

- Modulus takes both data and the governing physics into account to train a neural network that creates an AI surrogate model for digital twins.

- Omniverse enables the visualization and interactive exploration of digital twins using the output surrogate model from Modulus.

Together, the platform can create AI simulations in real time that are physics-informed, accurately reflect real applications such as carbon storage, and power its digital twin development.

For more information about how Earth-2’s digital twin platform uses Modulus and Omniverse to accelerate technologies that mitigate climate change and its impact, watch the AI Technology to Enable Net Zero GTC session. For more information about the Modulus integration with Omniverse, see Visualizing Interactive Simulations with Omniverse Extension for NVIDIA Modulus and the self-paced online course, Introduction to Physics-informed Machine Learning with Modulus.